About Me

My name is Ashik Simon, and I’m a systems engineer with a background in mechanical engineering from UCSD. My experience spans hands-on prototyping, fabrication, and scripting to automate tasks and create multidisciplinary solutions. Over the years, I’ve contributed to industry R&D projects and collaborative robotics teams, building a foundation to design and deliver products from concept to launch. This website highlights the projects and work I’ve been a part of, reflecting my passion for innovation and practical engineering.

Experience

Brain Corporation, San Diego, CA

Systems Engineer II

UCSD Morimoto Lab, La Jolla, CA

Graduate Student Engineer

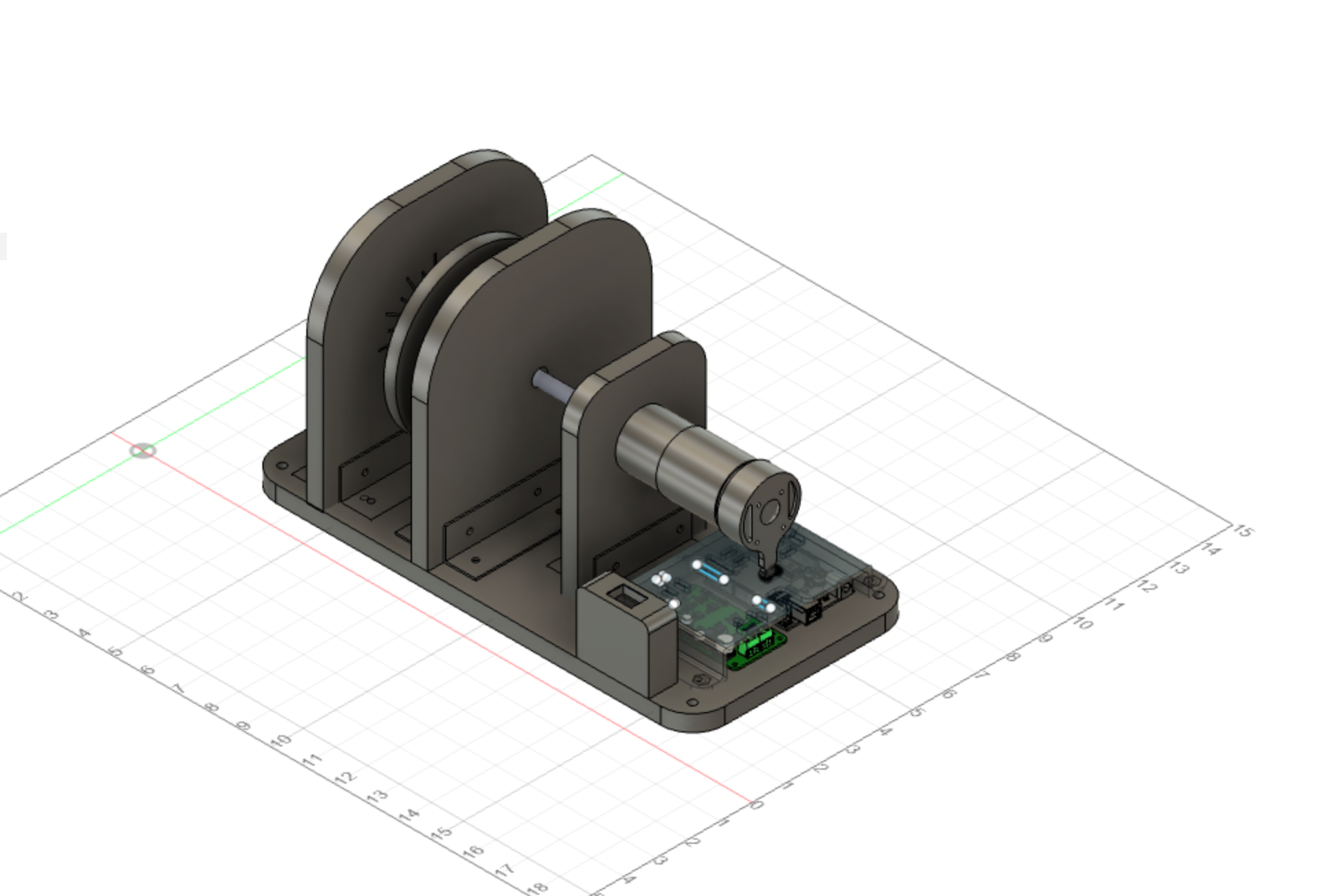

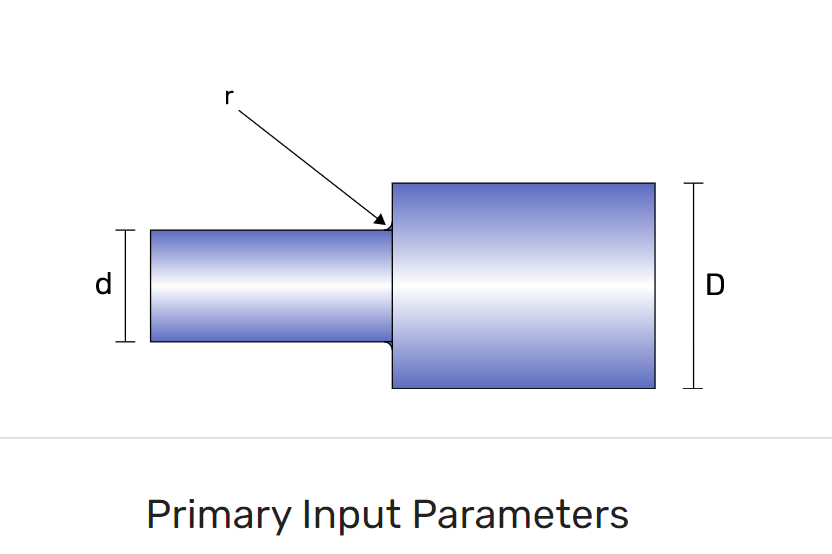

- Designed and validated a sub-$350 flywheel system for PID control education (MAE 143B)

- Built 30 systems using CNC waterjet, mills, and lathes; deployed to courses impacting 200+ students annually

- Developed a MATLAB GUI to visualize real-time position and velocity data and demonstrate PID parameter effects

- Integrated safety redundancies and course-specific features into system design

Hologic

R&D Engineering Intern to R&D Engineer I

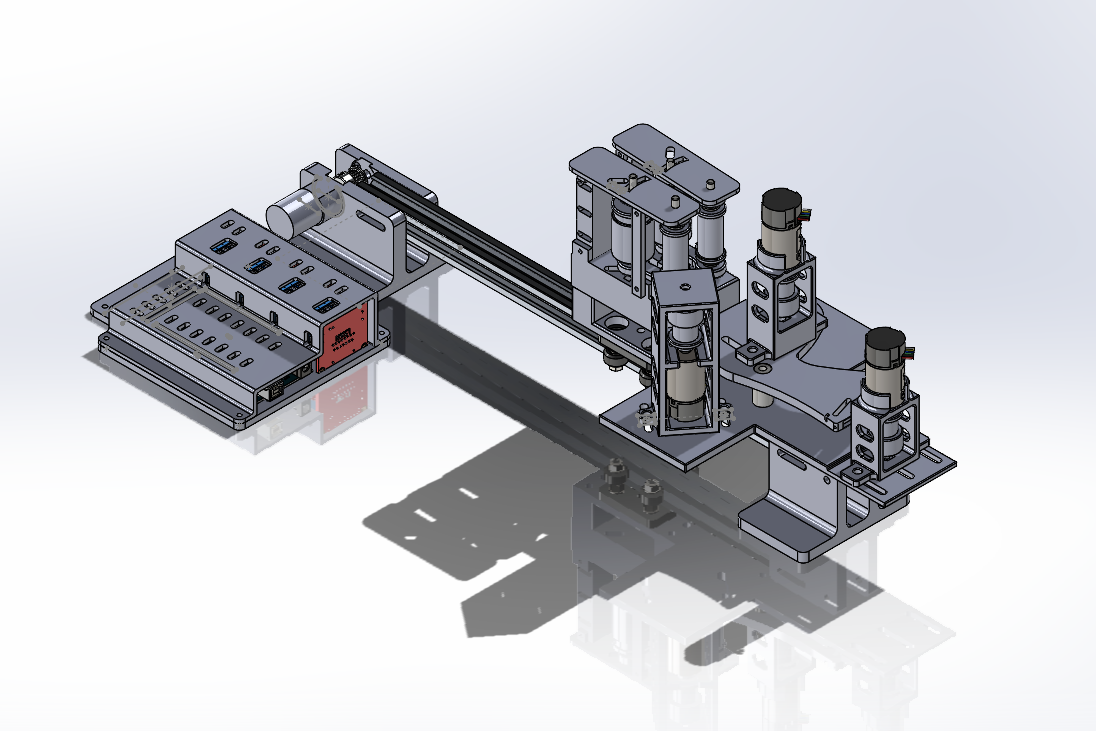

- Increase reliability on Hologic Panther Trax high volume lab automation system and Tomcat pre-analytical diagnostics instruments by troubleshooting mechanical issues

- Designed low-cost vibration monitoring hardware for detecting mechanical misalignment and wrote algorithms to classify data

- Researched, prototyped, and tested new product ideas for feasibility based on market needs

- Performed fault insertion testing on liquid handling robots to validate process controls to catch and handle edge cases

- Leveraged Python-based tools for signal processing, plotting, and analyzing large volumes of data to make well informed design decisions

General Dynamics NASSCO

Engineering Intern

- Reviewed and updated documentation/processes for the ESB and TAO ship programs

- Utilized AutoCAD to design manufacturable modifications for existing machinery

- Actively participated in implementing and monitoring continuous improvement initiatives to improve safety, improve quality, reduce cycle time, and reduce costs.

- Attained an understanding of shipbuilding logistics by regularly attending meetings with vendors, engineers, and customers

Design/Build/Fly

Fabrications Engineer

- The Design/Build/Fly (DBF) student team designs, fabricates, and demonstrates the flight capabilities of an electric-powered, radio-controlled aircraft that can best meet a given mission objective

- Construct lightweight RC airplane airframes utilizing various composites and adhesives including carbon fiber, kevlar, and fiberglass

- Prepare control surfaces and mount servos in innovative ways to minimize drag

- Create positive molds from foam using hot-wire and sanding with a high attention to detail inorder to prevent imperfections in final product

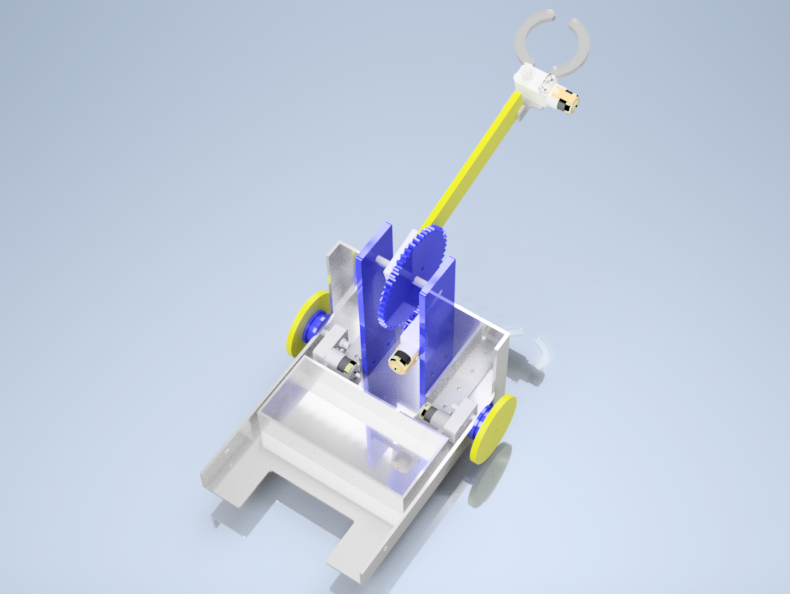

Yonder Dynamics

Mechancial Design Engineer

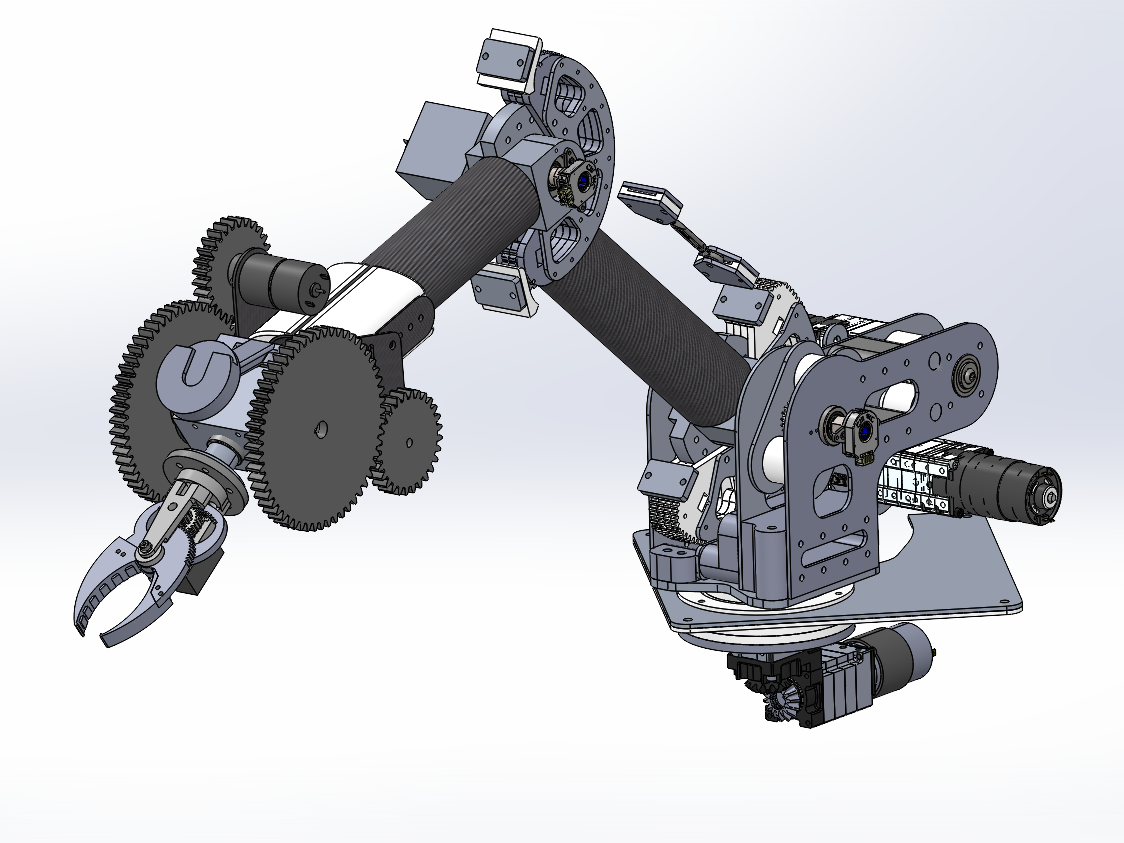

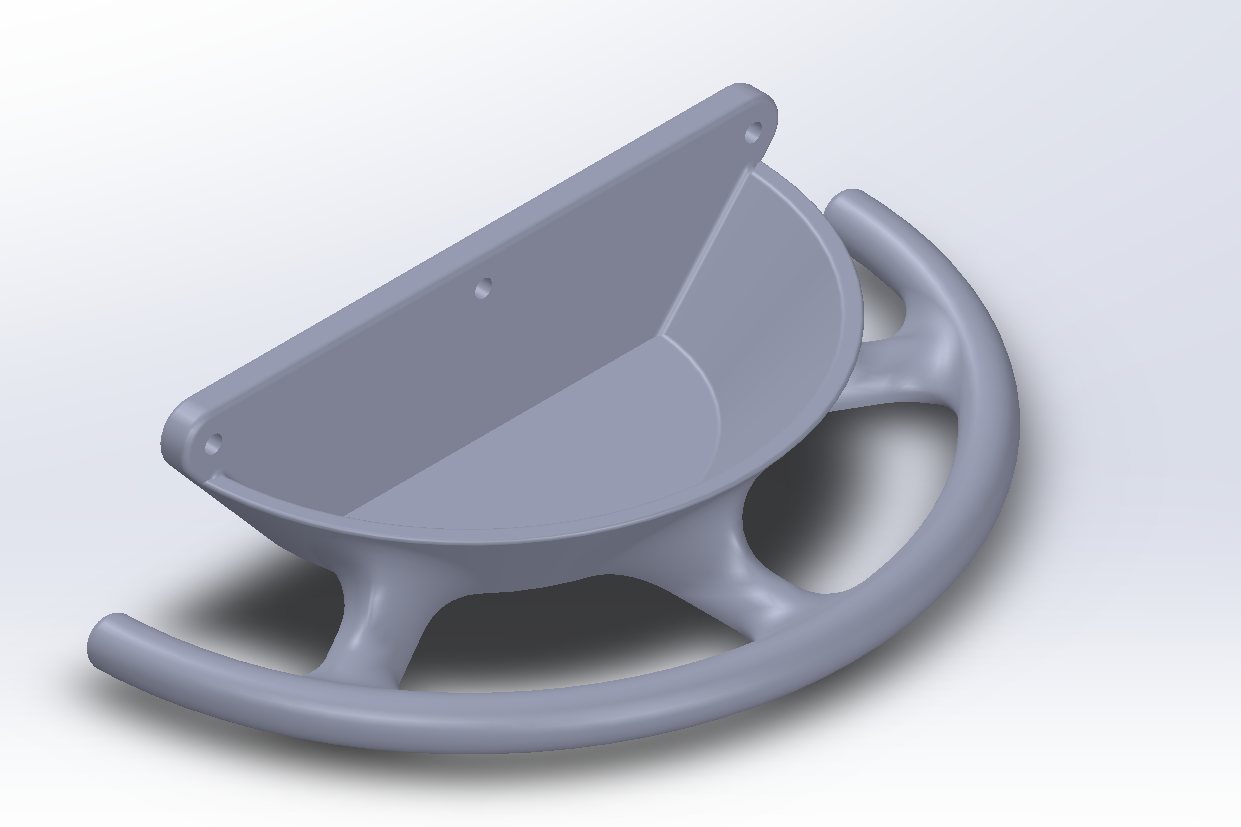

- Build a functioning mars rover style robot for the University Rover Challenge

- Responsible for creating a light weight high dexterity robot arm with six degrees of freedom

- Work with Solidworks modeling as well as physics risk reduction calculations

- Developed rotating base out of acetyl that is capable of withstanding high loads while remaining lightweight

- Designed cost-effective parts that are manufacturable with on campus equipment, primarily 3D printing and lasercutting

- Review technical documentation to look for design improvements

Craftvue

Founder

- Developed a custom application with Laravel web framework to help teachers manage data, organizesafety assessments, and material inventory

- Effectively communicated with clients to properly incorporate ideas and concepts into the application

- Successfully implemented in two schools with over 250 users.

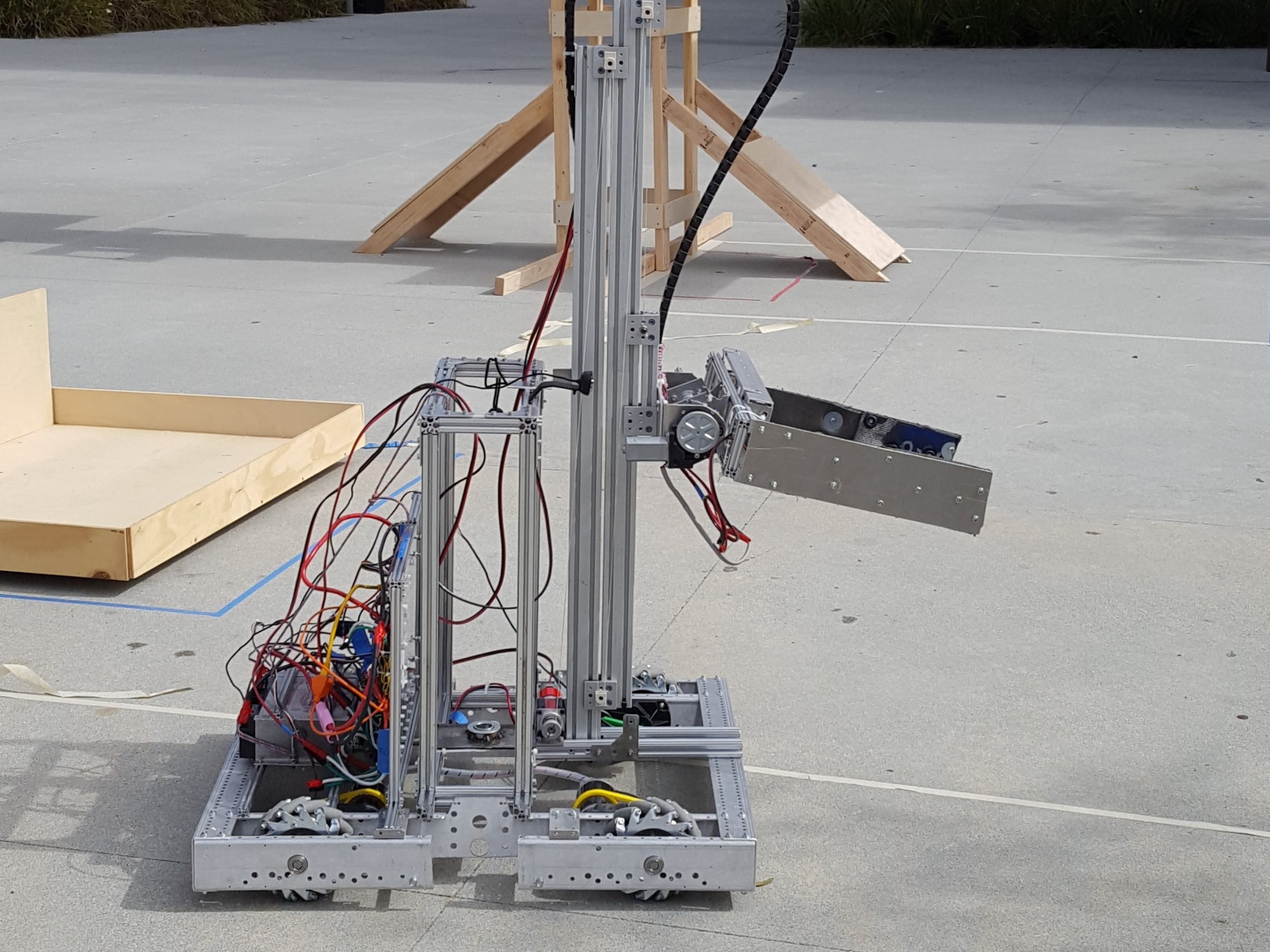

FIRST Robotics

Senior Subsystem Engineer

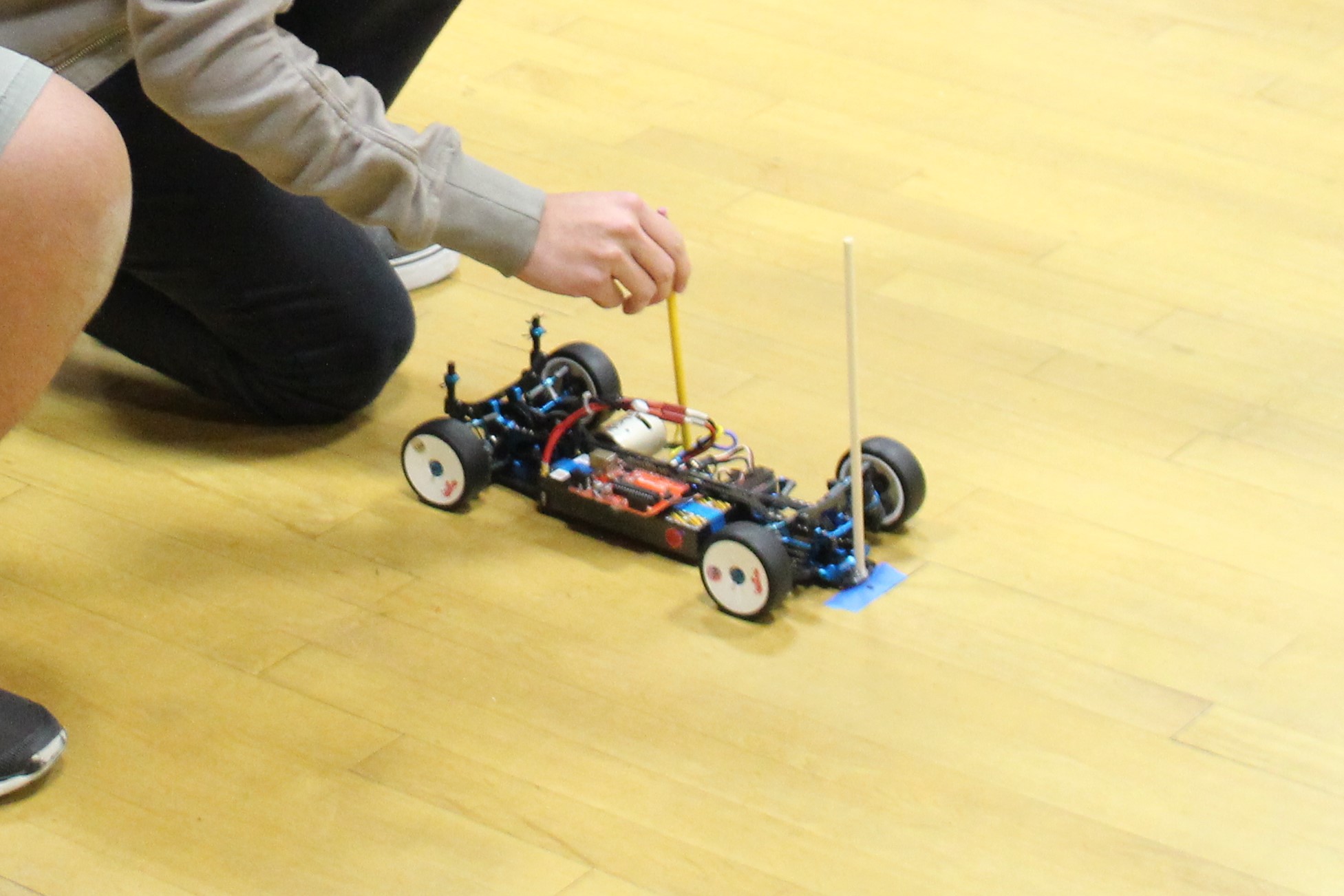

- Team of students and mentors construct a competitive robot within six weeks

- Oversee the integration of various subsystems by designing and fabricating parts as well as delegating tasks to newer members

- Thoroughly researched components to not violate competition rules and regulations

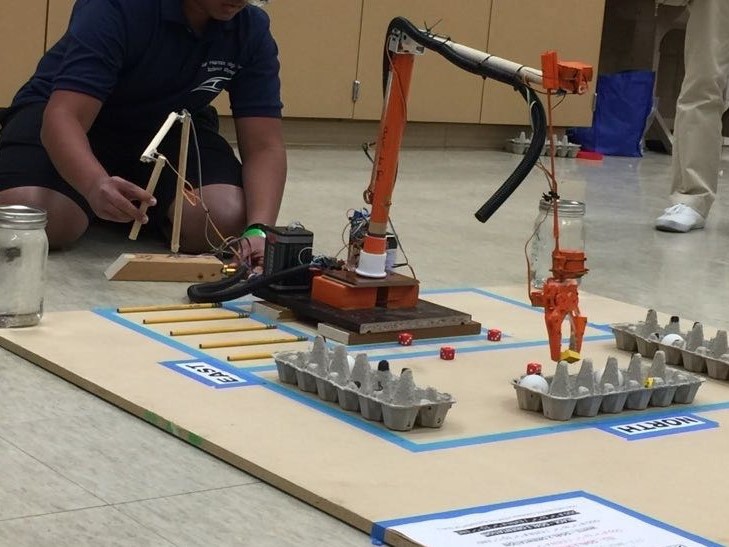

Northrup Grumman Challenge

Engineering Team Member

- Team-based competitions that are organized by Northrop Grumman with strict time constraints, budget constraints, and on the spot thinking for troubleshooting

- Developed a helium airship design the first year by manufacturing a custom aerodynamic balloonand implementing model RC aircraft controls

- Designed a hovercraft capable of carrying 15 lbs of payload through an obstacle course

Education

University of California San Diego, La Jolla

September 2018 - June 2022B.S. Mechanical Engineering

Relevant Coursework: Introductory Mathematical Physics, Elements of Materials Science, Engineering Graphics and Design, Business Project Management, Introductory Fluid Mechanics, MATLAB Programming for Engineering Analysis, Dynamics and Vibrations, Heat Transfer, Solid Mechanics I

September 2022 - PresentM.S. Mechanical Engineering

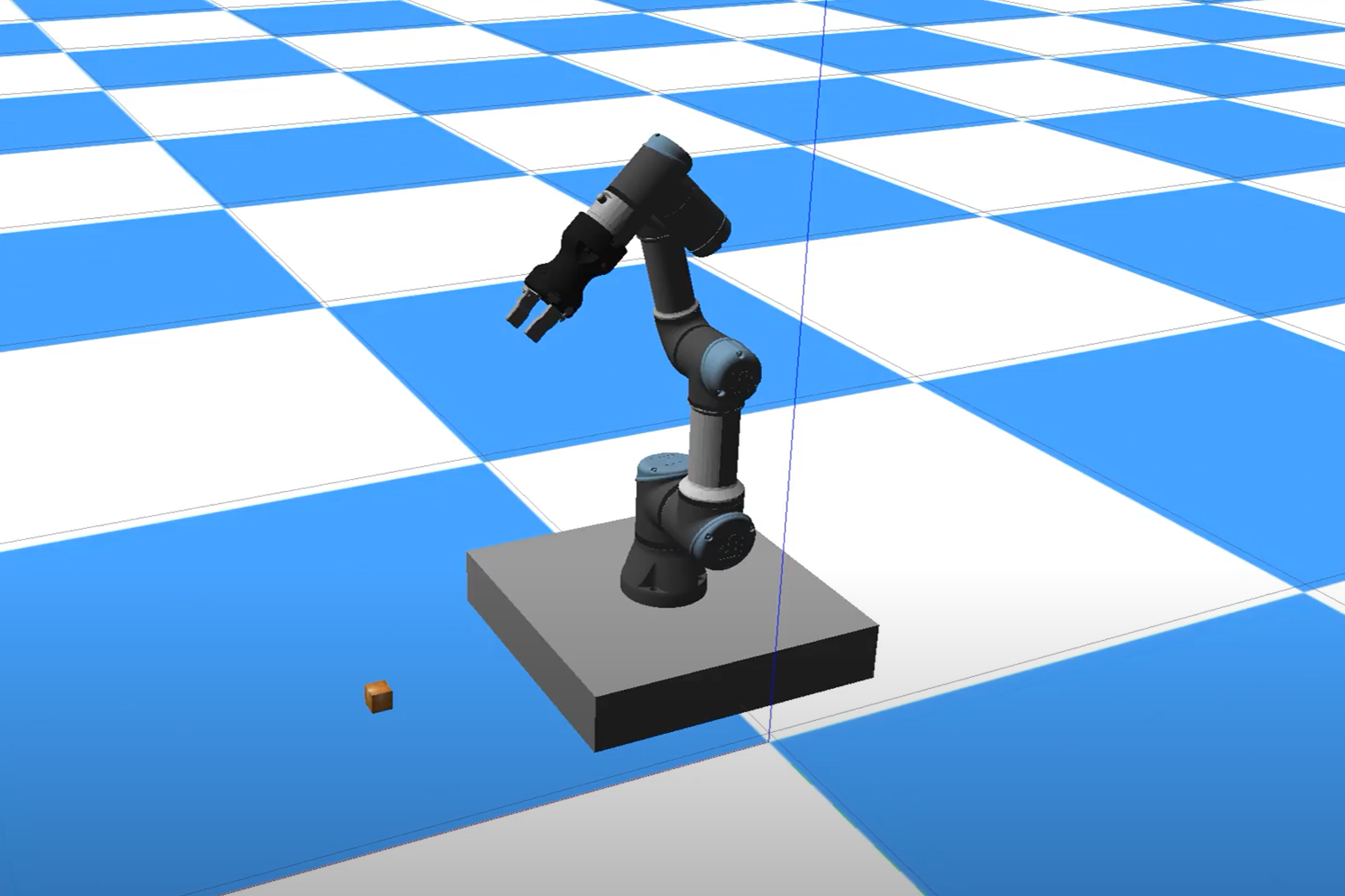

Relevant Coursework: Mechanics of Fluids, Solid Mechanics and Materials, Robotics, Design of Haptic Interfaces, Energy Systems and Renewable Energy, Ocean Tech Design, Biomaterials and Medical Devices

Projects

Skills

- Modeling and Analysis

- Autodesk Fusion 360

- Autodesk Inventor

- Solidworks

- MS Office

- LaTeX

- PhpStorm

- Github

- Arduino

- Java

- Php

- MatLab

- Laravel Framework

- Fabrication Prototyping

- Woodshop Machinery

- CNC

- Lasercutter

- 3D Printing

- Soldering

- Web Design